The Evolution of Manufacturing

In this article, we'll explore the many facets of it, including its history, current state, and potential future 3d printing manufacturing.Manufacturing processes have undergone a significant transformation in recent years, thanks to the advent of 3D printing technology. From rapid prototyping to full-scale production, 3D printing has revolutionized the way products are designed and manufactured.

Prototyping Redefined

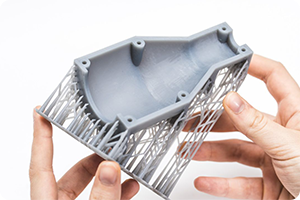

Traditionally, prototyping was a time-consuming and costly process that involved creating molds and tooling for each design iteration. With 3D printing, designers can now quickly produce physical prototypes directly from digital models. This not only speeds up the development cycle but also allows for more iterations and design variations.

The Rise of Additive Manufacturing

3D printing, also known as additive manufacturing, builds objects layer by layer, using materials such as plastics, metals, and ceramics. This additive process offers greater design freedom and complexity compared to traditional subtractive manufacturing methods. Complex geometries that were once impossible to produce can now be easily created with 3D printing.

From Prototype to Production

One of the most significant impacts of 3D printing on the manufacturing industry is its ability to seamlessly transition from prototyping to full-scale production. Companies can now use the same 3D printing technology to create prototypes, custom parts, and end-use products, streamlining the entire production process.

Overall, 3D printing is transforming the manufacturing industry by offering greater flexibility, efficiency, and customization. As the technology continues to advance, we can expect even more innovative applications and widespread adoption across various industries.